info@ringspann-kempf.de

Manufacturing Process

We produce nearly all cardan shaft components in-house with

state-of-the-art CNC machines, enabling

quick custom designs.

Raw Materials

Quality starts with top materials

We source forged and cast parts from Germany or Europe, prioritizing excellence.

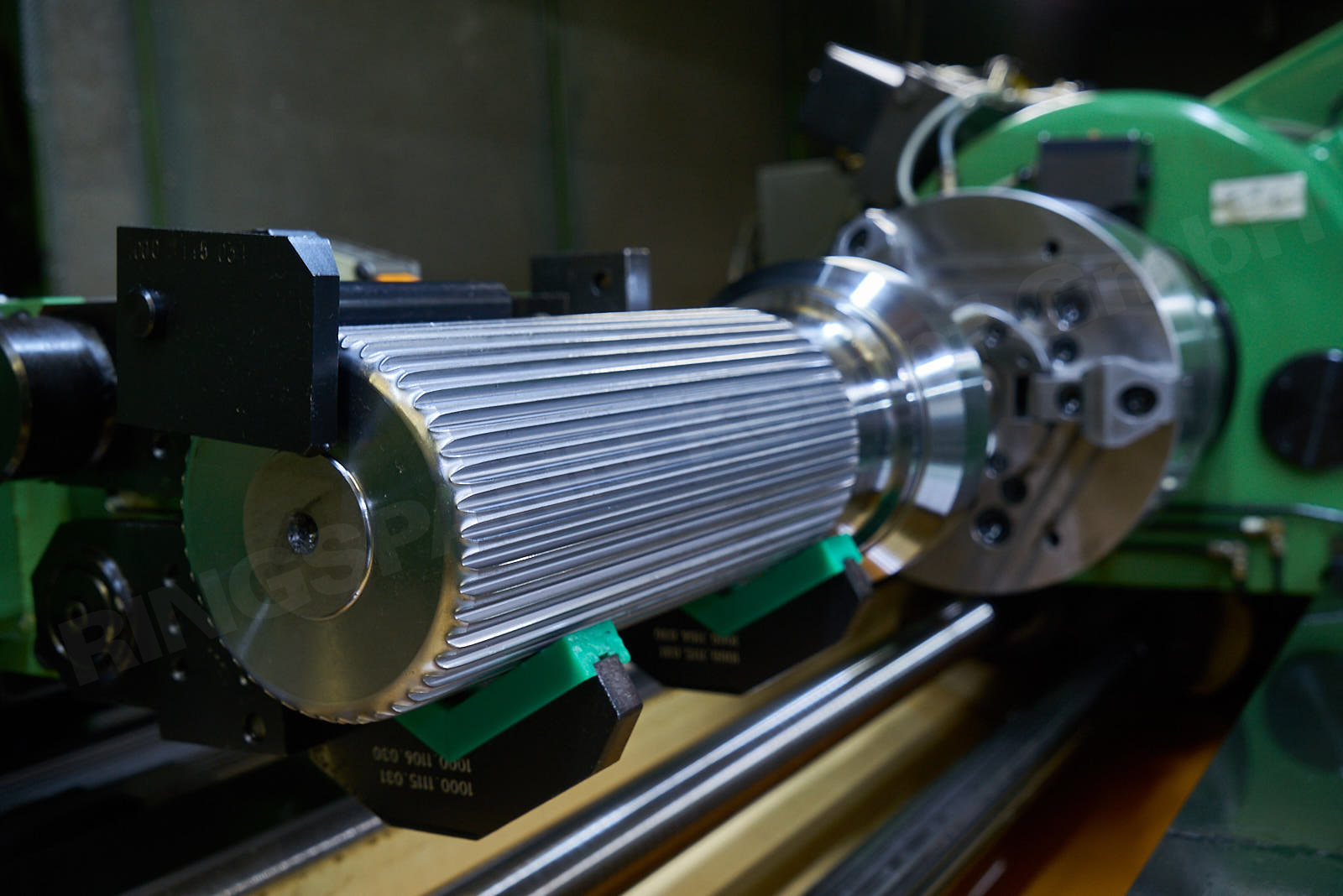

Machinery

Our modern equipment handles all production in-house.

1.

Machine Production

Nearly all components are crafted at our Gersfeld facility by skilled experts

Highlights include:

- Splined hub sleeves with polyamide 11 (Rilsan) coating

- Cold-rolled or hobbed shaft splines, boosting strength by 15-20% and reducing roughness for smooth, long-lasting performance

- Precision spiders built with proven technology for accuracy